Laser Next 2141

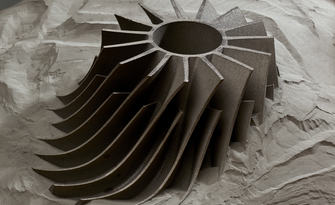

Direct Energy Deposition technology

A large machine, available in various configurations, for repairing, coating, adding custom parts.

FLEXIBLE

The most versatile platform available today for direct deposition additive manufacturing. Allows for easy processing of even the most complex part geometries.

RELIABLE

Unique and proven reliability, thanks to the experience and installations of the Prima Industrie Group’s Laser Next platform.

EFFICIENT

High efficiency (OEE) thanks to reduced downtime and maintenance. Fewer dedicated resources and simplified maintenance.

HIGH CAPACITY

Very large working area combined with reduced floor area occupied.

Laser Next 2141 with Direct Energy Deposition technology is based on a laser metal deposition process.

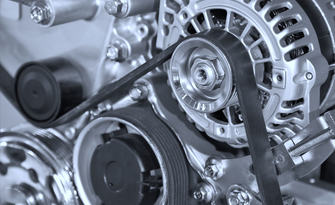

The system can handle both large and small parts and is suitable for repairs, reworking and coating.

The 5-axis platform is particularly suitable for all sectors that require movement flexibility and high precision.

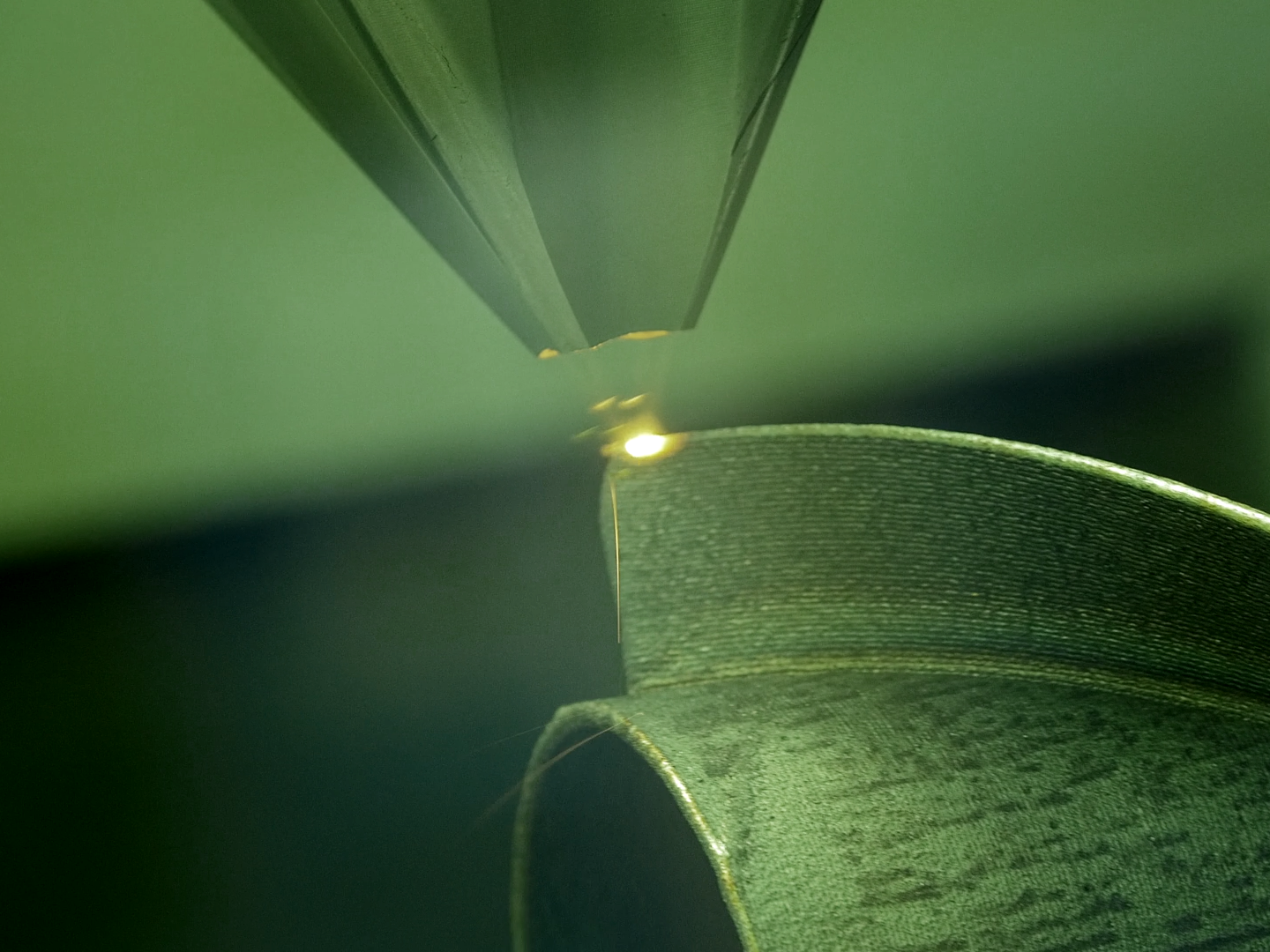

Thanks to Prima Additive’s Direct Energy Deposition technology, the powder deposited on the component is melted where it is needed by a deposition head that moves along 3 to 5 axes simultaneously.

5-axis motion with CNC control and full CAM suite

5-axis CNC system with integrated multiple crash protection, easy access and loading position. The addition of a tilting rotary table increases the machine’s flexibility by providing the system with two additional axes for more complex applications. An integrated powder feeder with 1-4 hoppers (1.5 litres), Prima CNC control, and CAM software provide users with all the tools they need to set up the machine according to the requirements of the application.

Suitable for parts manufacturing and reworking in a wide range of materials

Taking advantage of the workspace and easy installation, Prima Additive's largest Direct Energy Deposition machine can be used for complex repairs and reworking. To facilitate the needs of different industries, the Prima Additive team supports customers at every stage until optimal process parameters are achieved and a repeatable result is guaranteed.

Laser

Laser Next 2141 DED is available with a 1000W (CF1000), 2000W (CF2000) or 3000W (CF3000) ytterbium fiber laser source. Convergent CF fiber lasers are the result of Prima Industrie Group's experience in laser technology and have been developed for industrial and research applications: it is a compact and efficient high-power laser, producing from 1000 up to 3000 watts respectively, with a wavelength of about 1070nm.

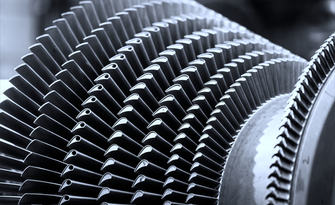

Rotary table

The rotary table is the 6th and 7th control axis for manufacturing of DED parts, repairing of critical components or rebuilding of damaged tools. The rotary axis (6th axis) provides continuous rotation of N x 360° clockwise or anti-clockwise on the vertical axis. The tilting axis (7th axis) provides rotation from -150° to + 150° on the vertical axis. The rotating tilt can sup port 300kg and has T-slots for fitting equipment.

- Working volume: 4140 x 2100 x 1020 mm

- Deposition rate: Max 50-70cm^3/h - typical 25-30cm^3/h (up to 100cm3/h with REAL_DED head)

- Laser: Fiber 1-6kW

Materials

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behavior of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Discover all the materials you can process with our DED machines

Optimize your Prima Additive machine

Software for DED

Direct Energy Deposition Technology

Cadcam software for direct energy deposition

Melting Pool Monitoring

Direct Energy Deposition technology

All controlled in real time

Real DED Laser Head

Direct Energy Deposition technology

The innovative and effective deposition head

Blue Laser Technology

Direct Energy Deposition Technology

Enhancing DED and Laser Welding technologies.

DED Laser Head Configurations

DIRECT ENERGY DEPOSITION TECHNOLOGY

Three options for the best results.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

See other products and choose the best solution for your business

IANUS Cell

Direct Energy Deposition technology

A multiprocess system based on a robotic arm for maximum flexibility.

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

DED kit

Direct Energy Deposition Technology

Unleash the power of direct energy deposition technology.

LASERDYNE® 795

Direct Energy Deposition technology