IANUS Cell

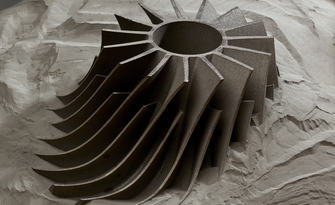

Direct Energy Deposition technology

A multiprocess system based on a robotic arm for maximum flexibility.

MULTIPROCESS

It can be configured on different laser processes: Powder-based Direct Energy Deposition, Wire-based Direct Energy Deposition, Laser Welding, Laser Hardening.

FLEXIBLE

Depending on the configuration chosen, it is possible to have a system capable of performing two different laser processes, thanks to the possibility of easily changing the head.

EASY TO INTEGRATE

Thanks to the integration with SIEMENS systems, on which this platform is based, the IANUS cell easily integrates with other machines already present in your factory.

CONVENIENT

Excellent value for money, combined with a network of suppliers of materials and consumables, as well as the application support of Prima Additive to make the most of the system.

The IANUS multiprocess robotic cell is based on a system consisting of an Autonox robotic arm and a laser source, inserted inside a cell with a working volume of 1600 x 1200 x 700 mm.

The peculiarity of this cell is the possibility of being configured for different laser processes such as Direct Energy Deposition based on the use of powder or on the use of metal wire as a starting material, but also other laser processes not necessarily in the spectrum of the additive manufacturing, such as laser welding (proximity or remote) and laser hardening.

The name of this solution comes from the Latin god Ianus, also known as the Italian "Giano", an iconic divinity with two faces. Just as the god Ianus has two faces, the Prima Additive IANUS robotic cell can also be configured to perform two different processes (for example additives and laser hardening) in the same machine, using the same laser source or different laser sources on the same robotic arm.

Thanks to the possibility of installing two dedicated warehouses, it is possible to switch from one application to another simply by changing the head installed on the robotic arm inside the machine itself. The head change, therefore, becomes comparable to a tool change, increasing the overall flexibility of the system.

This system presents a series of functional solutions for its inclusion in the factory of the future. In fact, it was developed by Prima Additive in collaboration with Siemens, a leading company in automation and digitalization with specific skills in the field of robotics and additive manufacturing. The integration between the technologies of Siemens and those of Prima Additive Srl is expressed, first of all, through the integration of the robotic arm and the CNC, through the Sinumerik Run MyRobot / Direct Control functionality.

Through this function, the user will be able to interface with the robotic cell using a single control console but above all he will be able to carry out the movement and programming of the robot using typical instructions of a machine tool, thus exempting him from knowing an additional language of robot specific programming. The integrated use of the CAD-CAM-CNC chain, made possible by the use of the NX platform and the Sinumerik One numerical control, is completed by the integration of digital solutions and data management.

The solution, based on the MindSphere open ecosystem, involves the use of Siemens Apps that allow you to view, manage and optimize production, such as Manage MyMachine, and remote monitoring and control systems, such as Manage MyMachine / Remote. To complete this digital offer, we find some specific applications, able to manage high-frequency data, based on the Industrial Edge for Machine Tools platform from Siemens.

In order to fully exploit the potential of Sinumerik One, the winning choice was to use the Create MyVirtual Machine, a key tool made available by the Siemens digital portfolio. This software is in fact able to generate a real digital twin of the system and has proved to be extremely useful for facilitating the engineering work in the various stages of development and optimization of the machine, also allowing a considerable reduction in time to market.

- Working Volume (LxWxH) 1600 x 1200 x 700 mm

- Dimensions (LxWxH) 3552 x 2751 x 2425 mm

- Weight 2000 kg

- Power supply 400 V / 50 Hz / 20 kW

- Number of integrated axes 6 to 8

- Axes speed 200°/s (acceleration 300°/s2)

- CAM Software (optional) NX Siemens

- CNC Software SINUMERIK ONE Siemens

Automation is possible by installing a conveyor belt and buffer

Materials

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behavior of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Discover all the materials you can work with our DED machines

Optimize your Prima Additive machine

Real DED Laser Head

Direct Energy Deposition technology

The innovative and effective deposition head

Inert chamber

Direct Energy Deposition technology

Processes titanium and other reactive materials to the highest quality

Melting Pool Monitoring

Direct Energy Deposition technology

All controlled in real time

Blue Laser Technology

Direct Energy Deposition Technology

Enhancing DED and Laser Welding technologies.

DED Laser Head Configurations

DIRECT ENERGY DEPOSITION TECHNOLOGY

Three options for the best results.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

See other products and choose the best solution for your business

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

LASERDYNE® 795

Direct Energy Deposition technology

The medium scale, multi-axis deposition machine for 3D fabrication, repairing, cladding, and coating.

DED kit

Direct Energy Deposition Technology