DED kit

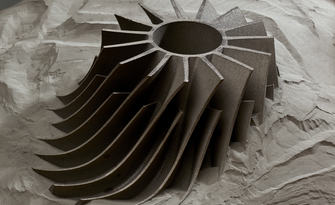

Direct Energy Deposition Technology

Unleash the power of direct energy deposition technology.

An innovative and multi-purpose laser head, a highly efficient laser source, and a flexible and reliable powder feeder that can be integrated on your machine or on a robotic system.

MODULAR

Modular design allows the laser head to be mounted in different configurations (straight, 90 degrees, with or without monitoring system). Easy installation on any type of machinery and easy maintenance of all the components of the DED kit.

FLEXIBLE

The kit can be integrated with any laser machine and robotic system. Possibility to satisfy different requests related to laser power, laser head configuration, process monitoring system, type and capacity of the powder.

EFFICIENT

The new nozzle design allows better powder use, while the fiber laser designed to offer high performance and efficiency guarantees low maintenance operations.

PROFITABLE

Low cost of ownership along with a wide network of suppliers for materials and consumables.

The DED kit includes all the equipment needed for direct energy deposition applications: an innovative and multi-purpose laser head, a highly efficient laser source and a flexible and reliable powder feeder. Prima Additive can offer the main components together or separately, allowing the retrofit of any laser machine or the integration on any type of robotic arm and structure.

Laser head

Modular and innovative laser head, designed to accommodate different laser processes and DED requirements. The laser head can be assembled in order to provide melt-pool monitoring (high-speed camera), pressurized optical path to avoid powder infiltration, and water-cooled additive-made nozzle for continuous additive depositions reducing powder adhesion risk during the process. Easy maintenance (cover glass and focal lens replacement), easy alignment of powder/laser spot and integration in any machinery and robotic systems.

Powder feeder

A powder feeding system developed to offer maximum flexibility and accommodate different materials. With the possibility of up to 4 powder hoppers and a capacity for up to 5.5 liters each, the system can be easily connected with any control system. Optional heating mats to keep the powder pre-heated, gas flow controller, and powder level sensors.

Laser source

Our high-power fiber laser systems integrate reliable, easy-to-maintain sources from top-tier manufacturers and can be adapted to include your preferred laser technology.

Other options

Along with the DED kit, Prima Additive can provide the rest auxiliaries for the DED process such as sieving system, vacuum cleaner as well as the AMXpress software plug-in (CAD / CAM) modified for any machinery.

Optimize your Prima Additive machine

Software for DED

Direct Energy Deposition Technology

Cadcam software for direct energy deposition

Inert chamber

Direct Energy Deposition technology

Processes titanium and other reactive materials to the highest quality

Melting Pool Monitoring

Direct Energy Deposition technology

All controlled in real time

Real DED Laser Head

Direct Energy Deposition technology

The innovative and effective deposition head

Blue Laser Technology

Direct Energy Deposition Technology

Enhancing DED and Laser Welding technologies.

DED Laser Head Configurations

DIRECT ENERGY DEPOSITION TECHNOLOGY

Three options for the best results.

Take advantage of our services

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Book a demo

Request a machine demo

Choose between a physical or virtual demo.

Experience the power of additive manufacturing with Prima Additive. Book a demo and explore our cutting-edge solutions for industrial metal 3D printing. Our demo service is available to show you how our technologies can be adapted to your production needs.

Contact us today and try it!

See other products and choose the best solution for your business

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

IANUS Cell

Direct Energy Deposition technology

A multiprocess system based on a robotic arm for maximum flexibility.

LASERDYNE® 795

Direct Energy Deposition technology