Cobalt Chrome alloys for DED

Materials for Direct Energy Deposition

Durability redefined.

Our state-of-the-art Direct Energy Deposition (DED) systems are at the forefront of transforming metal manufacturing processes. Specializing in cobalt-chrome alloys, we offer solutions that revolutionize the strength and durability of finished parts across various sectors. Cobalt chrome powders and alloys stand as pillars of resilience and innovation, especially when shaped by direct energy deposition (DED) technology. This technique, synonymous with precision and versatility, propels the creation of components that are not just larger but also stronger and with minimal waste, underscoring the advantages of cobalt chrome alloys in additive manufacturing processes.

Why Choose Cobalt-Chrome Alloys for Your Additive Manufacturing Needs?

Cobalt-chrome alloys are renowned for their exceptional properties, making them the material of choice for industries demanding the highest durability and performance standards. By choosing Prima Additive by Sodick's Direct Energy Deposition technology for processing these alloys, you unlock unparalleled benefits:

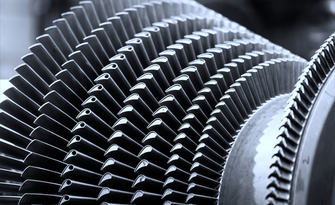

Exceptional Mechanical Wear Resistance

Our cobalt-chrome alloys exhibit outstanding durability, especially under high temperatures, ensuring your components operate flawlessly even in the most challenging conditions.

Superior Corrosion Resistance

With excellent resistance to corrosion, parts made from cobalt-chrome alloys withstand harsh environments, making them perfect for critical applications in the energy generation and oil & gas industries.

Prima Additive by Sodick's Expertise in Cobalt-Chrome Alloys

Leveraging Direct Energy Deposition, also known as Directed Energy Deposition or Laser Metal Deposition, our machines precisely fuse metals enabling superior material properties. Our expertise extends to processing a range of cobalt-chrome alloys, including:

- Stellite™ 6: Renowned for its balance of wear resistance, corrosion resistance, and the ability to withstand high temperatures.

- Stellite™ 21: Offers enhanced performance with excellent resistance to thermal shock and mechanical wear, ideal for hard-surface valve components and other high-wear applications.

Innovating for the Future with Prima Additive by Sodick

While these alloys represent a fraction of the materials compatible with Prima Additive by Sodick's machinery, the true extent of our systems' flexibility is much broader. Our open parameter system allows for the processing of any material from any manufacturer, offering unlimited potential to innovate and adapt to the evolving needs of metal additive manufacturing.

Our Direct Energy Deposition technology and cobalt-chrome alloys are shaping the future of manufacturing, offering solutions that are not just innovative but transformative. Embrace the change with us, and discover the competitive edge that Prima Additive by Sodick's additive manufacturing solutions can bring to your business.

Areas of application

Did you know that chromium and cobalt alloys are widely used in these sectors?

Need to make parts using a different material?

We are at your service to research and produce new materials suitable for additive manufacturing to meet your specific needs.

We will evaluate your business case and together develop the best material for your application.

Take advantage of our services

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Here are our solutions for processing Chrome-Cobalt alloys for DED

LASERDYNE® 811

Direct Energy Deposition technology

The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

Laser Next 2141

Direct Energy Deposition technology

A large machine, available in various configurations, for repairing, coating, adding custom parts.

DED kit

Direct Energy Deposition Technology