Prima Additive for the jewelry and design sector

Find out what we do for the jewelry and design sector

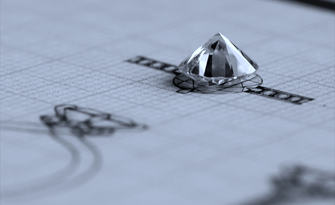

In the jewelry and design industry, creating intricate, high-quality pieces has traditionally required extensive craftsmanship, with each item demanding time and skill. Metal Additive Manufacturing (AM) has transformed this process, empowering designers to produce complex, stunning designs efficiently and at scale.

Prima Additive's metal AM solutions open up new creative possibilities with precious metals like gold and silver. Our technology supports both green laser and blue laser options for optimal results. In Powder Bed Fusion (PBF), our green laser solutions handle gold, silver, and other precious metals effectively, enhancing precision and material use. For Directed Energy Deposition (DED), our blue laser improves absorption in reflective materials, facilitating the production of intricate, custom pieces with integrated design features. Additionally, Wire DED with precious metals offers designers exceptional control, making it easy to create bespoke designs with high-quality finishes while optimizing material usage.

Prima Additive’s metal AM technology allows designers to bring previously unattainable designs to life. Our solutions enable the production of lightweight, visually stunning jewelry with intricate, integrated moving parts—all in a single print, eliminating the need for post-production assembly.

With Prima Additive's innovative metal AM solutions, designers can expand the limits of creativity and craftsmanship, delivering exceptional pieces in a competitive, fast-evolving industry.

Solutions

Find your ideal solution

Are you ready to completely rethink the manufacturing process of your jewelry or design objects? We will support you in choosing the most suitable materials for your application and in assessing the best printing strategy to create your parts.

In addition, we will support you in the design, prototyping and production of the final parts, giving you the opportunity to experiment with new shapes and digitally customize each part to create visually striking objects.

Main Applications of Metal Additive Manufacturing in the Jewelry Sector

Behind every innovation there is a Prima Additive machine

- Bespoke rings and other fine jewelry, allowing for unique expressions of personal style.

- Prototype models for large collections, enabling rapid iteration and refinement before final production.

- Restoration and replication of historical and antique jewelry pieces, preserving cultural heritage with modern technology.