Materials

Choose the metal that suits you.

Additive manufacturing is the innovative process of transforming metal into the component you need, even when it has to have very complex shapes or characteristics that are difficult or impossible to achieve with traditional industrial processes.

Yes, but what kind of metal?

Our 3D printing can work with different types of materials: aluminum, steel, copper, titanium, nickel, cobalt chrome. And we are here to advise you on the most suitable alloy for your production goals, depending on whether you choose Powder Bed Fusion or Direct Energy Deposition.

Discover the metal best suited for your production from the various additive manufacturing powders available.

Materials for Powder Bed Fusion

Aluminum alloys for PBF

Materials for Powder Bed Fusion

All the lightness of working with aluminum.

Steel alloys for PBF

Materials for Powder Bed Fusion

For quality that’s hard as steel.

Titanium alloys for PBF

Materials for Powder Bed Fusion

Lightness and biocompatibility all in one material.

Nickel alloys for PBF

Materials for Powder Bed Fusion

Endless strength, zero corrosion.

Cobalt Chrome alloys for PBF

Materials for Powder Bed Fusion

Biocompatible and durable.

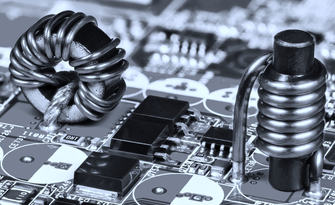

Copper alloys for PBF

Materials for Powder Bed Fusion

The best electrical conductivity at your service.

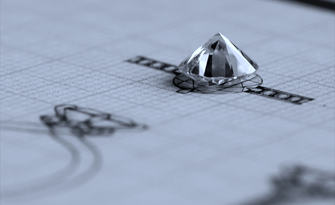

Gold and precious metals

Materials for Powder Bed Fusion

Impeccable results for perfect jewels.

Materials for Direct Energy Deposition

Steel alloys for DED

Materials for Direct Energy Deposition

Superior hardness.

Titanium alloys for DED

Materials for Direct Energy Deposition

Light, Strong, Advanced.

Nickel alloys for DED

Materials for Direct Energy Deposition

For stress and corrosion resistant parts.

Cobalt Chrome alloys for DED

Materials for Direct Energy Deposition

Durability redefined.

Copper alloys for DED

Materials for Direct Energy Deposition