Cobalt Chrome alloys for PBF

Materials for Powder Bed Fusion

Biocompatible and durable.

Focusing on the exceptional performance benefits, cobalt chrome alloys processed via powder bed fusion technology in metal additive manufacturing set a new standard for high-quality components. Cobalt chrome powders, expertly utilized by Prima Additive by Sodick's advanced systems, promise unparalleled strength, durability, and biocompatibility, redefining what's possible in the creation of superior components across various industries

Unlocking Innovation with Biocompatible and Durable Solutions

Engineered for excellence, Prima Additive by Sodick’s Laser Powder Bed Fusion technology offers unparalleled benefits for cobalt-chrome alloys:

Biocompatibility

Safeguarding patient health in medical and dental applications, our technology ensures materials that are not only safe but conducive to human health

Exceptional Strength and Durability

Forge parts that withstand the test of time and stress, embodying resilience in every layer

Resistance to Wear and Corrosion

In the face of challenging environments, our solutions stand tall, ensuring longevity and reliability

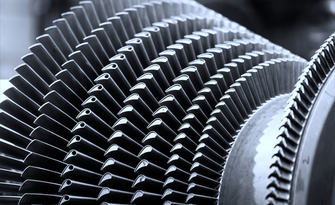

Widely celebrated for its robust properties, cobalt-chrome is the material of choice across diverse sectors. From high-precision laser melting for medical and dental implants to crafting components for gas turbines, engines, and transmissions, its application scope is vast. Furthermore, its unique biocompatibility opens new avenues in jewelry manufacturing, marrying aesthetics with health.

Main Alloys for Your Projects

Prima Additive by Sodick machines are designed to work with a variety of cobalt chrome alloys, ensuring flexibility and adaptability for your specific needs. Some of the primary alloys include:

- CoCr-W: Known for its wear resistance, suitable for dental and medical implants.

- CoCr-Mo: Offering excellent strength and corrosion resistance, ideal for aerospace and automotive parts.

Beyond the Standard: Our Open Parameters Approach

Our commitment to innovation and competitiveness is embodied in our machines' ability to process a wide range of materials. While the aforementioned alloys represent the most suitable options, Prima Additive by Sodick's solutions go beyond, capable of working with any type of material made by any manufacturer, thanks to our open parameters. This flexibility ensures that whatever your project requires, our machines can adapt to meet the challenge.

Areas of application

Did you know that chromium and cobalt alloys are widely used in these sectors?

Need to make parts using a different material?

We are at your service to research and produce new materials suitable for additive manufacturing to meet your specific needs.

We will evaluate your business case and together develop the best material for your application.

Take advantage of our services

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Here are our solutions for processing Chrome-Cobalt alloys for PBF

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

300 Family

Powder Bed Fusion Technology