Gold and precious metals

Materials for Powder Bed Fusion

Impeccable results for perfect jewels.

The world of metal additive manufacturing is witnessing a transformative era with the advent of powder bed fusion technology, especially when it comes to working with gold alloys, gold powders, and other precious metals. Prima Additive by Sodick stands at the forefront, pioneering solutions that harness the full potential of these materials, ensuring impeccable results for the jewelry industry and beyond.

Unleashing the Potential of Precious Metals

The unique properties of precious metals pose distinct challenges in additive manufacturing, notably their high reflectivity which results in suboptimal absorption for infrared lasers. Prima Additive by Sodick's cutting-edge technology provides an answer to this obstacle. Our machines are equipped with state-of-the-art green lasers, emitting at a wavelength of 532 nm, ideal for processing reflective alloys with unparalleled quality and consistency. This optimal absorption ensures flawless execution in the creation of precious metal pieces.

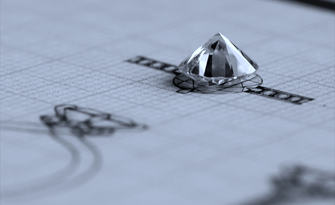

Precision Engineering for Immaculate Jewels

The jewelry sector demands nothing less than geometric perfection, a prerequisite for truly enhancing jewelry design. Prima Additive by Sodick's solutions, featuring green laser technology with a laser spot size of just 35 microns, offer extraordinary precision. This enables the crafting of intricate designs and detailed features in precious metals, previously unattainable with traditional manufacturing methods.

Achieving Unprecedented Material Density

A hallmark of Prima Additive by Sodick's technology is its ability to achieve material densities nearing 99% on gold and precious metals. Such density ensures that the final product not only exhibits superior structural integrity but also allows for post-processing to achieve a polished finish indistinguishable from traditionally cast jewelry. This opens up new possibilities for incorporating complex geometries, lattice structures, and organic forms into jewelry designs, empowering creators to explore new dimensions of creativity.

Precious Metals Processable with Prima Additive by Sodick Machines

Prima Additive by Sodick's machines are versatile, capable of processing a broad spectrum of precious metals and alloys. Key materials include, but are not limited to:

- Gold and its alloys, for creating luxurious and intricate jewelry pieces.

- Silver, known for its aesthetic appeal and conductivity, perfect for both traditional and contemporary designs.

- Platinum and palladium, offering exceptional durability and rarity for high-end jewelry.

Beyond the Basics: Expanding the Realm of Possibilities

While the aforementioned metals represent the tip of the iceberg, Prima Additive by Sodick's technology does not stop there. Our machines are designed with open parameters, allowing them to work with any type of material made by any manufacturer. This opens up endless possibilities for jewelers and designers to innovate and explore new horizons in jewelry making.

Forge Ahead with Prima Additive by Sodick

Discover the boundless possibilities of additive manufacturing for precious metals with Prima Additive. We invite you to explore our solutions and learn how we can support you in achieving your creative and manufacturing goals. Contact us to embark on a journey of innovation and excellence in jewelry design and production.

Embrace the future of jewelry manufacturing with Prima Additive by Sodick, where innovation, precision, and creativity converge to redefine the boundaries of design and craftsmanship.

AREA OF APPLICATION

In this industry, great things can be done with Prima Additive by Sodick solutions

Need to make parts using a different material?

We are at your service to research and produce new materials suitable for additive manufacturing to meet your specific needs.

We will evaluate your business case and together develop the best material for your application.

Take advantage of our services

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Here are our solutions for processing gold and precious metals for PBF

300 Family

Powder Bed Fusion Technology

High productivity and precision for medium and big-sized components manufacturing.

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Green 150

Powder Bed Fusion Technology