Or, to put it more simply, with this technology it is possible to produce metal components with complex geometries that otherwise could not be produced with other traditional technologies.

The benefits are considerable, starting from a business model truly tailored to your needs, offering previously unexplored production opportunities.

In fact, with Additive Manufacturing it is possible to completely flip the manufacturing paradigm from a model that requires large warehouses to on-demand production, or from standard production to customized production, making components lighter and more functional.

The two main processes of Additive Manufacturing

Complex geometries or targeted repairs, cladding, and recoating. All tailor-made.

Prima Additive by Sodick develops and offers innovative laser systems for both major metal additive manufacturing processes: Powder Bed Fusion (PBF) and Direct Energy Deposition (DED).

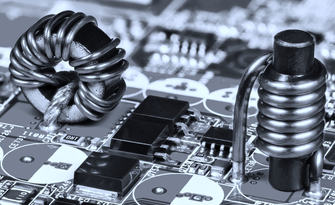

With Powder Bed Fusion technology, also known as Selective Laser Melting, you can make components having very complex geometries, with internal channels or very small parts, thus giving the finished piece a truly functional design.

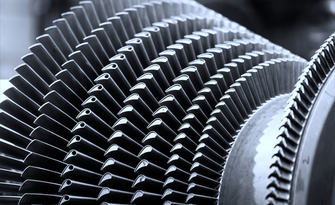

With Direct Energy Deposition technology, also known as Laser Metal Deposition, you can choose to deposit metal powder exactly where it is needed. In this way, you can repair, customize or coat parts with high added value, reducing waste and embracing the Circular Economy model.

But technology alone is not enough; Prima Additive by Sodick also provides all the application support needed to derive the best possible benefits from the additive manufacturing process. Thanks to our experience, you can learn how to redesign your components to take full advantage of this technology. By doing so, you can produce more functional and lightweight parts or integrate multiple components into one, thanks to the freedom that additive technology offers.

Try it now!