Prima Additive for the energy, oil & gas sector

Find out what we do for the energy, oil & gas sector

In the energy, oil and gas sectors, equipment faces some of the most extreme working conditions, with exposure to high temperatures, intense pressure, and corrosive environments. These factors lead to rapid wear and tear on critical components, often resulting in costly downtime and frequent part replacements. Traditional manufacturing methods, with their extended lead times and high costs for custom parts, especially in remote locations, struggle to meet the urgent demands of this industry.

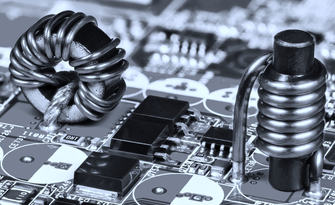

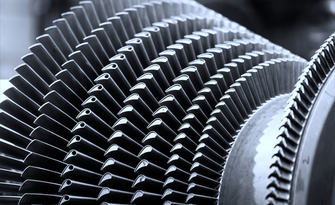

At Prima Additive, we harness the power of metal additive manufacturing (AM) technologies like Powder Bed Fusion (PBF) and Direct Energy Deposition (DED) to transform how components are produced, maintained, and repaired. Our solutions provide a clear advantage by enabling on-demand production of complex parts, drastically reducing the need for expensive spare part inventories and minimizing the downtime associated with waiting for replacements. PBF is particularly suited for manufacturing lightweight, high-performance components such as turbine blades and heat exchangers, which are essential for improving energy efficiency and increasing the longevity of equipment in oil refining and power generation processes.

For equipment exposed to constant wear, DED offers a precise method for repairing and restoring damaged parts, enabling them to return to service more quickly and with improved durability. This technology excels in industries where equipment is subjected to harsh conditions, such as offshore drilling, turbines, and pipeline systems, providing protective coatings that extend the lifespan of critical machinery.

By integrating Prima Additive's PBF and DED technologies into your operational workflow, you can reduce both the costs and complexity of maintaining high-value equipment. These technologies allow companies to enhance operational efficiency, optimize component performance, and ensure that their production remains sustainable and competitive in the fast-evolving energy industry. Moreover, our metal AM solutions support sustainability efforts by reducing material waste, streamlining supply chains, and extending the life of vital equipment, helping energy companies align with their environmental goals.