Copper alloys for PBF

Materials for Powder Bed Fusion

The best electrical conductivity at your service.

Copper alloys and copper powders unlock a host of benefits in the realm of powder bed fusion, bringing the transformative power of copper into the hands of creators. Let's delve into the essence of these materials and the unparalleled advantages they offer when processed using Prima Additive by Sodick's cutting-edge metal additive manufacturing systems.

The Core of Innovation: Copper Alloys and Powder Bed Fusion

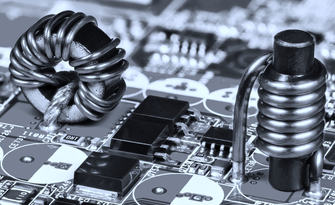

Powder bed fusion (PBF) epitomizes additive manufacturing by layering materials to create objects from 3D models, moving beyond traditional subtractive methods. This process, particularly when applied to copper alloys, is renowned for its precision and efficiency. The unique properties of copper alloys—marked by their excellent electrical and thermal conductivities, alongside notable strength and ductility—make them indispensable in sectors like electronics, aerospace, and automotive manufacturing.

Unlocking the Potential of Copper Alloys with Prima Additive by Sodick Technology

Working with copper alloys through laser powder bed fusion technology, especially with Prima Additive by Sodick's solutions, offers significant benefits:

Exceptional Corrosion Resistance

Our copper alloys ensure your components withstand the test of time, maintaining integrity in challenging environments

Superior Mechanical Properties

Strength and durability are hallmarks of parts produced with our technology, capable of enduring demanding applications

Optimized for Complexity and Precision

Prima Additive by Sodick's machinery leverages green laser technology, enabling the processing of copper and its alloys with high quality and repeatability. This allows for the creation of parts with complex geometries that traditional manufacturing methods cannot achieve

Outstanding Thermal and Electrical Conductivity

Leverage the innate qualities of copper alloys for applications requiring high conductivity, from electronics to cooling systems

Electrify Your Innovations with Precision Green Laser Technology

Prima Additive by Sodick's Powder Bed Fusion systems redefine the boundaries of metal additive manufacturing with their state-of-the-art green laser technology. This advanced capability allows for the processing of not only a diverse range of copper alloys but also pure copper, achieving a remarkable material density exceeding 99.5%. Such high density is pivotal for applications where electrical conductivity is paramount, ensuring your projects benefit from the utmost in quality and repeatability. Moreover, the precision of this process is unparalleled, thanks to a laser spot size of merely 35 microns, offering unmatched detail and accuracy in every print. This breakthrough opens new horizons for innovation, enabling the creation of components with exceptional electrical and thermal properties, all while maintaining extreme quality and repeatability in every piece crafted.

Key Copper Alloys for Prima Additive by Sodick Machinery

Prima Additive by Sodick's machines are adept at processing a wide range of copper alloys, including:

- CuSn10: a tin bronze alloy, is celebrated for its wear and corrosion resistance, combined with good elasticity. It's ideal for parts requiring durability and resistance to environmental conditions, such as bearings and springs.

- Pure Copper (Cu): stands out for its unparalleled electrical and thermal conductivity, alongside high ductility, making it essential for electrical wiring, components, and heat dissipation applications.

Beyond the Standard: Exploring Material Possibilities

While the listed copper alloys represent the most suitable candidates for Prima Additive by Sodick's machinery, the horizon of possibilities is far from limited. Prima Additive by Sodick's open parameter system means that any material, regardless of the manufacturer, can be processed. This flexibility opens the door to custom solutions and innovations, ensuring that your manufacturing needs are not just met but exceeded.

Areas of application

Did you know that copper alloys are widely used in these sectors?

Need to make parts using a different material?

We are at your service to research and produce new materials suitable for additive manufacturing to meet your specific needs.

We will evaluate your business case and together develop the best material for your application.

Take advantage of our services

Request an application assessment

Feasibility assessment

Let's break down the barriers to entry for Additive Manufacturing!

Application support

Transforming ideas into industrial reality

Metal Additive Manufacturing offers limitless opportunities for innovation, but successfully integrating it into an industrial workflow requires the right expertise and support.

Design support

Redefining design for performance and efficiency

The true power of metal additive manufacturing (AM) lies in its ability to create complex geometries that were once impossible with traditional methods.

Training in additive manufacturing processes

Comprehensive training for Metal Additive Manufacturing

Investing in metal additive manufacturing means embracing an innovative, high-performance technology that requires in-depth knowledge and hands-on experience to maximize its potential.

Qualification and certification

Ensuring quality and compliance in additive manufacturing

In metal additive manufacturing, the quality of a component is not only measured in terms of dimensional accuracy and mechanical properties but also in its ability to meet strict industry certification standards.

Here are our solutions for processing Copper alloys for PBF

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Genius 150

Powder Bed Fusion Technology

Great versatility thanks to multi-laser technology.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

300 Family

Powder Bed Fusion Technology