Leading the Charge towards Additive Manufacturing Innovation

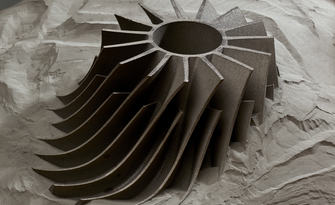

Prima Additive is a real game-changer in the world of additive manufacturing, leading the way with its focus on Directed Energy Deposition (DED) technologies. This includes important processes like Laser Metal Deposition and, of course, Rapid Coating or, as some prefer to call it, High-Speed Laser Cladding. This technology uses a laser beam to deposit materials onto a workpiece, creating a top-notch coating that sticks to the substrate on a metallurgical level.

High-Speed Laser Cladding is renowned for its precision, control, and its knack for creating hard coatings with impressive mechanical properties, like increased hardness, corrosion resistance, and wear resistance. We are sure that Rapid Coating will soon become the main standard for industries looking for high-quality coating solutions. The coatings made with High-Speed Laser Cladding are not only strong but also perform exceptionally well, meeting the varied needs of different industrial applications.

Now, it’s important to clarify that Laser Cladding can also be crucial in environmental conservation, for example when performing brake disc coating. Data shows that 21% of particulate emissions from combustion vehicles come from brakes. Each time a vehicle brakes, in fact, part of the brake disc material wears off and is released into the atmosphere in polluting particles. For this reason, coating brake discs is key to cutting down pollutant emissions, aligning with strict environmental standards like the upcoming Euro 7 norms, soon entering into force.

Using High-Speed Laser Cladding for brake disc coating is more than just a technology upgrade; it’s a step towards a greener future, helping industries stick to their sustainability goals and shrink their environmental footprint. It’s about being responsible and adopting eco-friendly practices, not just complying with the rules.

Prima Additive is on a mission to redefine industrial standards, developing Additive Manufacturing solutions that are innovative, high-quality, and green. It’s about transforming the way industries operate, making sure the solutions provided are groundbreaking and sustainable. Prima Additive’s approach is paving the way for a future where excellence, cost-saving, and eco-consciousness go hand in hand.

With its cutting-edge technologies and commitment to innovation, Prima Additive is enabling industries to go beyond the usual, enhancing their business.

Empowering the Future with IANUS Cell

IANUS by Prima Additive is a groundbreaking machine in the world of additive manufacturing solutions. It is a multiprocess robotic cell designed to be versatile, configurable, and capable to handle a variety of laser processes, including direct energy deposition, laser welding, and laser hardening.

One of the advantages in integrating a IANUS cell into your production line is how it meshes perfectly with Siemens technologies. This seamless integration allows users to interact with the robotic cell through a unified control console, making robot handling and programming easier and really effective. IANUS cell is user-friendly and efficient, removing the hassle and complexity usually associated with others robotic interfaces.

The compact and flexible design of the IANUS cell makes it a perfect fit for continuous production environments. It’s designed to keep cycle times to a minimum and ensure operations run smoothly and efficiently, streamlining the flow of material.

Now, when it comes to Rapid Coating solutions, the IANUS cells by Prima Additive are top-notch. They offer highly efficient solutions for all applications, including brake disc coating. The integration of IANUS cells in a brake disc coating process guarantees optimal results, boosting the efficiency and precision of the coating technology.

For the brake disc coating application, we have developed a fully automated solution based on our IANUS cell. Thanks to this system, it is possible to have fully automated production to work 24/7 within automotive industry factories.

Automation and integration are a game-changer for high-volume industrial production, especially for meeting the ever-changing demands of the automotive sector. That's the reason why Prima Additive isn’t just about providing solutions; it’s about creating value and boosting productivity. The company engages in extensive dialogues with clients to get to the heart of their unique needs and challenges. It’s about understanding what the client really needs and offering solutions that are tailor-made for them.

Moreover, Prima Additive offers robust post-sale support, ensuring that customers are not left alone once the deal is done, building relationships that stand the test of time and ensuring that the evolving needs of clients are met with innovative and reliable solutions.

Shaping the Future of Additive Manufacturing

Prima Additive, as we said before, stands out as more than just a provider of additive manufacturing solutions: we want to be a pioneer in shaping the future landscape of additive manufacturing with our integrated solutions and an unwavering commitment to excellence and innovation.

We are proud that nowadays our company is recognized as a reliable partner in all the main processes of laser-based metal additive manufacturing, offering its partners comprehensive solutions designed to elevate client efficiency, aligning seamlessly with the principles and objectives of Industry 4.0.

Prima Additive’s ventures in high-speed laser cladding and rapid coating are not just innovative; they are revolutionary, setting new benchmarks and standards in the industry. We want to pave the way for a future where additive manufacturing is synonymous with sustainability, quality, and precision, where the boundaries of what is possible are constantly being pushed and redefined.

In constant dialogue with our customers, we can ensure that all the solutions provided by Prima Additive are meticulously designed to meet the specific, varied needs of industries, offering a perfect amalgamation of innovation, efficiency, and reliability. We always try to create solutions that are tailor-made to address the unique challenges and requirements of each industry, ensuring our clients optimal results and maximum impact on cost savings.

For more information on how Prima Additive can revolutionize your processes with high-speed laser cladding and other advanced additive manufacturing solutions, contact us.

Discover the future of manufacturing with Prima Additive!