Prima Additive will present its highly innovative and smart solutions at the Formnext trade show in Frankfurt am Main from 19 to 22 November (Hall 12.0, Stand E81).

Do you want to come and visit us at Formnext? Request a free ticket:

• Prima Additive at Formnext 2024 – Prima Additive will showcase its advanced metal additive manufacturing solutions, focusing on industrial scalability and automation in Hall 12.0, Booth E81.

• New Theme: “Scaling AM for Industrial Production” – Highlighting Prima Additive’s commitment to transforming additive manufacturing for large-scale applications, including fully automated systems now serving the automotive industry.

• IANUS Robotic Cell – A multiprocess robotic cell on display in its Rapid Coating configuration for brake discs. This flexible system supports various laser processes and integrates seamlessly with production lines through Siemens software.

• Print Genius 150 Double Wavelength – The only system on the market combining an infrared and a green laser, enabling the processing of a wide range of materials, including reflective metals, all within a single platform.

Frankfurt am Main, November 19-22, 2024 – Prima Additive will showcase its latest innovations at Formnext 2024 in Frankfurt. With a focus on transforming metal additive manufacturing into a truly scalable industrial solution, Prima Additive’s stand in Hall 12.0, Booth E81 will present cutting-edge technology designed to meet the demands of high-output production environments.

This year, Prima Additive introduces the theme “Scaling AM for Industrial Production”, underscoring its commitment to advancing additive manufacturing through automation and modularity. A highlight of this year’s showcase is Prima Additive’s recent deployment of robotic cells for Rapid Coating, a high-speed laser cladding process. These systems, now adopted by automotive manufacturers and Tier 1 suppliers, enable fast, high-quality coating of brake discs with dual metal layers to minimize particulate pollution, a requirement under the forthcoming Euro 7 standard set for 2026. This fully automated technology operates 24/7, bringing metal additive manufacturing to mass production for the first time and marking a shift from prototyping to large-scale component manufacturing.

On Display at Formnext 2024: IANUS Robotic Cell and Print Genius 150 Double Wavelength

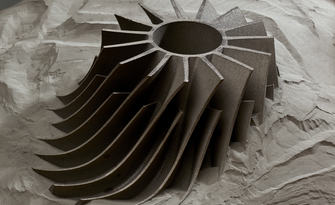

Visitors to the Prima Additive booth will experience two of the company’s most advanced solutions in action: the IANUS multiprocess robotic cell and the Print Genius 150 Double Wavelength. Both systems reflect Prima Additive’s mission to lead additive manufacturing into the realm of high-volume industrial production.

The IANUS robotic cell is a versatile multiprocess system that can be configured for a wide range of laser processes. While it will be showcased at Formnext in a configuration for Rapid Coating of brake discs, its applications extend well beyond this single process. The IANUS cell is fully customizable and adaptable, capable of performing tasks such as Direct Energy Deposition with both powder and wire, as well as laser welding and hardening. This flexibility makes it an ideal solution for manufacturers with diverse production needs. Built on a robust Siemens software infrastructure, the IANUS cell is designed to integrate seamlessly into automated production lines, featuring advanced capabilities such as Siemens’ Sinumerik One CNC and Insights Hub for streamlined control and connectivity across the factory.

Alongside the IANUS cell, Prima Additive will exhibit the Print Genius 150 Double Wavelength, a groundbreaking system with the unique capability of combining an infrared laser and a green laser within the same platform. This innovative configuration allows users to work with a broad range of materials, including highly reflective metals like copper and precious alloys, which are typically challenging to process with conventional lasers. The Print Genius 150’s dual-wavelength setup enables manufacturers to alternate between the two lasers on the same work area, ensuring precision and high-quality results across different materials—all within a single system.

Prima Additive’s approach to additive manufacturing exemplifies the company’s commitment to transforming metal AM from specialized applications to mainstream, large-scale production. By creating versatile and scalable solutions, Prima Additive is empowering manufacturers to integrate additive processes directly into their production environments.

Discover Prima Additive’s advanced technologies at Formnext 2024, and learn how we are shaping the future of industrial additive manufacturing.

Do you want to come and visit us at Formnext? Request a free ticket: