Cologne, 14-18 March 2023 - Prima Additive will be present at the IDS International Dental Show trade fair in Cologne (Hall 10.1, stand C041) with solutions that respond to current trends in the dental sector.

Additive technologies have arrived in the dental world for a couple of decades now and guarantee an outstanding level of precision and productivity. Prima Additive's solutions, thanks to their high productivity, innovative laser configurations, open parameters and the ease with which it is possible to change the material, prove to be an optimal and flexible solution for the needs of this sector.

At the Cologne fair, Prima Additive’s booth will be in collaboration with 8853 S.p.A. which, through its 88dent division, is a customer and partner of Prima Additive in the development of solutions optimized for the needs of the dental technicians.

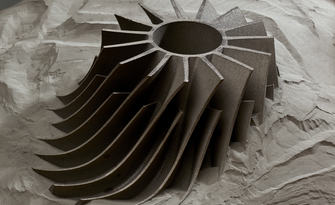

At the stand it will be possible to see the Print Sharp 150, a compact single laser Powder Bed Fusion solution. The system is consisting of a cylindrical working volume of 150 mm diameter and 160 mm height, which proves to be a particularly suitable solution for the dental sector thanks to the possibility of creating up to 180 items with a single print job lasting just over three hours.

The system has optimised gas flow for minimum nitrogen or argon consumption and material can be changed in less than two hours thanks to modular components. Print Sharp 150 is equipped with a 300W single mode IR fibre laser source, which is air-cooled, so no external unit cooler is required.

A single line width of 0.1mm and a minimum layer thickness of 0.02 mm can be achieved for high precision. A reliable and compact optical scanning system offers high processing speeds and various scanning strategies.

Intuitive, intelligent control software allows rapid orientation of parts and defining of machine functions by the operator. With an open, easy-to-use process parameter management tool, you can also change key print parameters, select your scanning strategy, and export machine-readable files. Prima Additive's 150 series is Industry 4.0 Ready and allows the integration of monitoring sensors and connection through different standards for IoT functions.

88dent, which has a Prima Additive Print Genius 150 dual laser machine installed in its laboratory near Milan, thanks to the use of additive manufacturing is able to provide a complete digital workflow, suitable for both small laboratories and large centers production, who can take advantage of 88dent's expertise in proposing specific solutions for their needs. Through a dedicated portal available on the 88dent.com website, the customer can upload the file (or several files) of the prosthesis to be created with just a few clicks and within 24/48 hours can receive the semi-finished product or the structure to be finalised.

It is precisely thanks to the interaction between a system manufacturer and an end user that the best results come out in terms of process optimization and services that can be offered to all those in the dental sector who want to acquire solutions for metal additive manufacturing. This synergy will be the key to Prima Additive's participation in the IDS tradeshow: a highly specialized support for a very demanding industry in terms of component quality, material properties and production needs.