Prima Additive will be showcasing its latest innovations at Formnext 2021, the international meeting point for the next generation of intelligent industrial production, which will take place in Frankfurt, Germany, from 16 to 19 November 2021.

As the motto chosen for this event suggests, “Good to Grow”, in a period in which many industrial sectors have finally returned to expand and look towards the future, Prima Additive presents its solutions for smart and sustainable growth. Prima Additive will be happy to meet Formnext visitors in person and safely again to showcase its latest future-proof innovations.

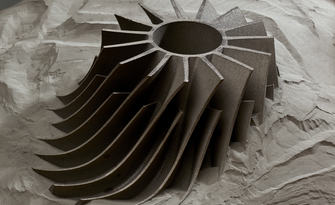

Previewed at Formnext, the Print Genius 150 Double Wavelength is the new product of Prima Additive's 150 series with Powder Bed Fusion technology. What makes this machine unique is the innovative configuration of the laser sources: a 300 W infrared laser and a 200 W green laser, which can work alternately on the same work area. In this way, it is possible to select the best wavelength for optimizing the material absorption of the laser radiation. For instance, you can choose IR radiation for steel alloys, titanium, nickel, chromium-cobalt, or green radiation for pure copper, aluminum, or other highly reflective materials. The Print Genius 150 Double Wavelength features a build volume with a diameter of 150 mm and a height of 160 mm and it is possible to equip the machine with several different options. These include a system to vary the position of the laser beam focus according to the application, a double pre-heating system to heat the surface of the powder bed both from above and from below (up to 300 ° C), a high-speed coaxial pyrometer to control the temperature in real-time, and 2 cameras to monitor the process and the powder bed. All process parameters, such as laser power, layer thickness, scanner speed, and so on, can be set in real-time during the job. The Prima Additive 150 series is Industry 4.0 Ready and allows the integration of monitoring sensors and connection through different standards for IoT functions.

Another solution on display at the Prima Additive stand is the Print Genius 250, the ideal solution for high productivity metal printing applications, able to reduce production times thanks to its 500 W single-mode dual laser, combined with intelligent software for a quick orientation of the pieces and for the definition of the machine parameters. The build volume of 258x258x350 mm makes the machine suitable for the production of medium-sized components. The optimized gas flow, resulting in minimal consumption, and the ability to change the material completely in less than 2 hours are other strengths of this innovative machine. The Print Genius 250 is equipped with a dual-line filter unit for the recirculation of the gas inside the work area, which maintains a high degree of cleanliness of the machine and minimizes the replacement of parts subject to wear. The new HMI allows the user to monitor the construction environment in real-time and generate reports with all of the main printing parameters. The Print Genius 250 is suitable for a wide range of materials: stainless steel, maraging steel, high-temperature nickel-based alloys (Inconel), titanium, cobalt-chromium, aluminum, copper, and high hardness steels for the mold sector.

The latest Prima Additive development for Direct Energy Deposition additive manufacturing processes, the Laserdyne 811 DED, will be also on show in Frankfurt. The machine provides precision, productivity, and flexibility for a wide variety of components. The controller supports 7 axes of simultaneous motion, and integrated automation to load and unload components and subassemblies, using robotics, automated stock inputs, a turn-table, or an outfeed platform. The Laserdyne 811 is an extremely flexible solution: additive, welding, drilling, and cutting 3D and 2D components are supported by a single machine. With the BeamDirector® and quick-change nozzles, in a matter of seconds, the machine can be made suitable for the application at hand. The machine features a working volume of 1100 x 800 x 600 mm, a deposition rate up to 70 cm3/h, and an inert chamber option in order to print reactive materials such as Aluminium and Titanium. The machine can be equipped with a REAL_DED (REal-time Adaptive Laser beam for Direct Energy Deposition) laser deposition head, developed and patented by Prima Additive to increase the performance and the efficiency of the deposition process and let the end-user adapt the laser beam spot dimensions in real-time during the process.

In addition to live demonstrations of the exhibited machines, face-to-face meetings with Prima Additive experts will also be possible and visitors can discover the complete range of services that maximise the benefits and profit of the additive technology for its entire life cycle.