Circular Economy inspired

Thanks to the possibility of repairing metal parts, it is possible to extend the life cycle of the component, maintaining its value over time and regenerating worn components. In this way, production becomes more sustainable since what until yesterday had to be rebuilt from scratch now can be repaired.

Direct Energy Deposition technology therefore fits fully into the circular economy paradigm thanks to the possibility of depositing metal only where needed. In this way, it is possible to restore worn parts on components with high added value.

A convenient process

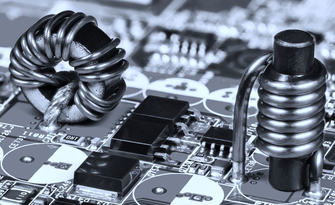

Thanks to this technology, the deposited material adheres to the substrate thanks to a fusion process: in this way, resistance and mechanical properties completely comparable to those of the original component are obtained.

Among the options that Prima Additive offers to facilitate repair operations, there is a vision system that allows you to identify the edges of the component to be repaired and thus precisely deposit the metal coating with which to restore the functionality of the component.

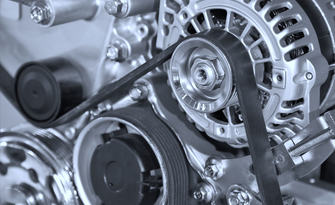

Addressing many different industries

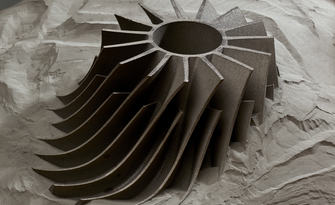

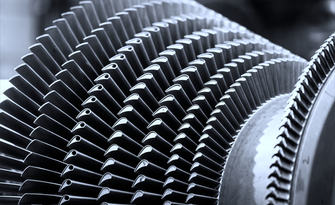

This type of process is widely used, for example, in the aeronautical and oil and gas sectors for the repair of turbine blades, but it can also be used to repair shaped surfaces or worn edges on tools or molds.

Thus, not only production but the entire supply chain is revolutionized in one fell swoop: less transport of components from one place to another, less warehouse storage, less use and movement of raw materials, and more repairs.