The second edition of the Innovation Days, the international event dedicated to innovative technologies for Additive Manufacturing and sheet metal processing, was held in the new Advanced Laser Center of Prima Industrie. Over 300 guests, including customers, universities and research centers, were welcomed to the event.

During the Innovation Days 2019 the new generation of systems for the additive manufacturing of metal components by Prima Additive were presented. The innovations shown during the event cover both AM technologies: Powder Bed Fusion (PBF) and Direct Energy Deposition (DED).

The new systems have been designed following the group’s Open Innovation approach, which focuses on the needs and applications of customers, ensuring a close partnership with the end users of the technologies and a strong adherence to market demands.

Another important drive for group’s innovation projects is sustainability. Following its “green” vocation, Prima Industrie has developed high energy efficiency products that reduce consumption compared to traditional systems and guarantee high performance. Prima Additive products also allow customers to embrace the business paradigm of the Circular Economy, which aims to maintain the value of products and materials for as long as possible, transforming resources at the end of their life cycle into new inputs in the value creation process.

Many companies in different industrial sectors are adopting additive manufacturing technologies for their production, also to satisfy the increasing requests for customization of products by the market. Prima Industrie meets these needs with products that make it possible to exploit all the competitive advantages of Additive Manufacturing, thanks to high productivity, first-rate process reliability, excellent quality of finished parts and excellent performance-price ratio.

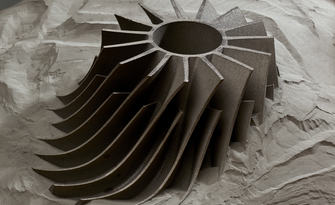

At the Innovation Days, Prima Additive presented the Print Genius 250, the new PBF machine with a construction volume of 262x262x350 mm, suitable for the production of medium-sized components. Print Genius 250 is the ideal solution for high productivity metal printing applications thanks to its dual 500 W single-mode laser, which reduces production time, combined with intelligent software for fast part orientation and for the definition of machine parameters.

Optimized gas flow, minimizing consumptions, and the capability of complete material change in less than 2 hours, are other strengths of this innovative machine. Print Genius 250 is equipped with a 2-line filter unit for the recirculation of the gas inside the work area, which maintains a high degree of cleanliness of the machine and minimizes the replacement of parts subject to wear. The new HMI allows to monitor in real-time the building environment, the building plate, the dispenser, the recoater, and generates reports with all traceable key printing parameters.

Print Genius 250 is suitable for the processing of a wide range of materials: stainless steel, maraging steel, high-temperature nickel-base alloy (Inconel), titanium, cobalt-chromium, aluminum and copper alloys, and high strength steel.

As part of the Direct Energy Deposition technology, at the Innovation Days was also presented the Laserdyne 430 DED, the compact and accurate laser metal deposition platform with a working volume of 585x400x500 mm, a high build rate and excellent end-part properties, suitable for 3D fabrication, reworking, and repairing.

The Laserdyne 430 DED is equipped with the Advanced Head, the innovative multipurpose DED laser head with modular design that can be mounted in different configurations to adapt to multiple laser processes. Some of the strengths of the new head are: the fusion pool monitoring, the pressurized optical path that avoids dust infiltration, and the water-cooled additive-made nozzle for continuous deposition, which reduces the risk of powder adhesion during the process. The head also offers easy maintenance and fast alignment of the powder / laser spot.

The Advanced Head can be mounted on all Prima Additive Direct Energy Deposition products, and is also available as part of Prima Additive’s Laser Metal Deposition Kit, which includes the head, a high-efficiency laser source, a flexible powder feeder, and a CAM software for offline programming. The kit can be integrated into any machinery and robotic system.

The flexibility of the Laserdyne 430 DED can be further increased thanks to the addition of an optional roto-tilting table, which adds two more axes for more complex applications.

The 4000 sqm of the Advanced Laser Center are dedicated to the new research and innovation laboratory of advanced laser production systems. The premises are built with the latest sustainable building criteria and use geothermal systems and solar panels to minimize environmental impact.

The new facility is part of a wider program for the renewal of the group’s sites in Torino area, which began in 2016 with the construction of the new Collegno Headquarters and Tech Center, which will be completed within the next year with the construction of the new production plant for laser machines, currently located in another area of the city. The total investment on the territory is around 25 million euros and will allow Prima Industrie to increase efficiency bringing the sites closer together in a single large complex, improving the customer experience in the areas dedicated to visitors, and being able to count on more modern and organized work environments.