Automated Powder Management System

AUTOMATION FOR POWDER BED FUSION

AUTOMATION FOR POWDER BED FUSION

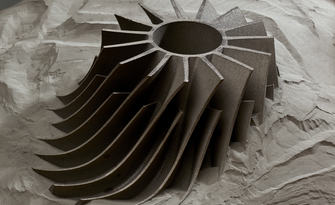

The automated powder management system is a flexible solution to operate safely with Prima Additive large machines, optimizing machine loading and unloading operations and, consequently, increasing productivity.

Designed to work together with the Print 400 series machines, which boast an extractable work area, it allows all powder removal operations to be carried out from the print area by means of suction, rotation, and localized vibration in order to remove all the powder from the component.

After the depowdering phase, the system collects all the residual powder in a controlled atmosphere, then automatically sieving it.

Finally, the recovered and sieved powder is automatically returned to the machine by means of a system of pneumatic conveyors which operates in a closed loop.

The flexibility of this system allows you to connect up to five Prima Additive Print 400 series machines to the same Automated Powder Management System. In this way, operations and costs are optimized thanks to a flexible industrial system for metal additive manufacturing.

Powder Bed Fusion Technology

Application support

Open innovation

Circular economy inspired

© Prima Additive S.r.l. | Corso Re Umberto, 54 - 10128 Torino (TO) Italia | Share Capital € 116.860,77 fully paid up | VAT 11434740012 - C.C.I.A.A.Torino 1213183 | Reg. Impr. Torino n. 11434740012

Company subject to direction and coordination of the shareholder PRIMA INDUSTRIE S.p.A., single-member company (ex art. 2497 C.C.)