Software for PBF

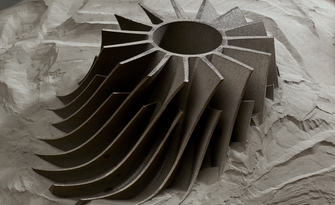

Software for Powder Bed Fusion technology

All the support you need to prepare files for producing additive manufacturing parts.

Materialise Magics RP is versatile software for preparing data files for producing Additive Manufacturing parts.

Magics RP includes all the basic functions to prepare a file for printing: reading different 3D model formats, repairing errors in the model, modifying the design, adding media for printing and preparing the build platform. In addition to the basic software (Magics RP), the suite is completed with SG & Structures modules.

Metal support generation module (SG+)

In metal additive manufacturing, support structures have greater functionality than simply supporting a part during the build process. An optimal metal support minimises deformation, prevents build problems and reduces post-processing work.

The Magics SG+ module provides all the tools you need to find the optimal orientation of the part, the right type of support, good anchorage, heat transfer and more. With the guidance of the Magics SG+ module, printing metal parts will no longer be an impossible challenge.

Materialise Magics' Structures module is designed to help reduce the weight and use of materials in projects. Regardless of whether you want to hollow out a part and fill it with a lightweight structure, convert a part into a lattice structure or create functional surfaces, the user-friendly wizard in our Structures module will guide you every step of the way.

With the Materialise Magics structures module you can:

- Reduce dust consumption and production costs

- Add resistance to parts

- Reduce distortion (due to heat generated during the construction process)

- Create porous models

- Design unit cell structures to create a lattice structure

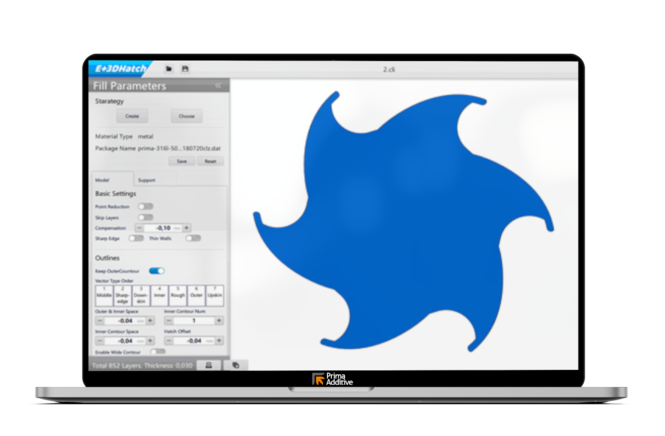

This is the build post processor for writing process parameters for the Powder Bed Fusion machines. The tool is an add-on to the Materialise Magics software. Starting from an STL cad file, with the Materialise BPP tools you can manage and customise all the process parameters that the machine is able to control, thus obtaining free read/write access to the production parameters.

For example, you can modify parameters such as:

• laser power;

• scanning speed;

• scanning strategy;

• hatch distance;

• scan type: downskin, upskin, inner contour, outer contour, etc.

As an alternative to using customised parameters, you can select optimised process parameter packages for each material type, such as:

• aluminium;

• titanium;

• nickel;

• stainless steel and so on.

See other products and choose the best solution for your business

Print Sharp 150

Powder Bed Fusion Technology

Designed for R&D applications, for processing steel, aluminum, nickel, titanium, and cobalt chrome alloys.

Print Green 150

Powder Bed Fusion Technology

Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

Print Sharp 250

Powder Bed Fusion Technology